API 653 Internal Tank Inspections: What You Need to Know

The EPA requires that field-erected ASTs have formal internal inspections. Here's what you can expect.

To ensure the safety and reliability of large above ground storage tanks (ASTs), regular inspections are required. In additional to the monthly in-service inspections and formal external inspections, one of the most critical inspections is the API 653 internal tank inspection.

In this article, we will explore the basics of the API 653 internal tank inspection and its importance in maintaining the integrity of storage tanks.

What is the API 653 Standard?

API 653 is a standard developed by the American Petroleum Institute (API) that outlines the minimum requirements for the safe operation, maintenance, and inspection of above-ground storage tanks. It covers the inspection, repair, alteration, and reconstruction of steel aboveground storage tanks used in the petroleum and chemical industries.

What type of tank requires an API 653 internal inspection?

The API 653 standard applies to above-ground storage tanks (ASTs) that are field-erected or field-built, made of steel or other metal alloys, and have a diameter of 30 feet or more, or a height of 50 feet or more. These tanks are typically used to store petroleum, chemicals, and other hazardous materials in industrial facilities such as refineries, chemical plants, and terminals.

What is the purpose of an internal inspection?

API 653 internal inspections identify any defects or potential issues that could compromise the integrity of above-ground storage tanks. These inspections are designed to detect issues such as corrosion, leaks, and structural damage that can lead to tank failures, spills, and other hazardous incidents.

Additionally, the API 653 inspection fits with the Environmental Protection Agency's (EPA) Spill Prevention, Control, and Countermeasure (SPCC) rule, which requires tank owners and operators to take measures to prevent and respond to potential oil spills and other types of releases. By conducting API 653 inspections on their ASTs, facility owners can ensure that their tanks are in compliance with the SPCC rule and take steps to prevent hazardous incidents.

How often is an internal inspection required?

The frequency of API 653 internal inspections depends on a range of factors, including the tank's size, age, and the materials it stores. In general, a tank must undergo its first internal inspection 10 years after the construction date, and then normally every 20 years thereafter. If the inspector finds corrosion, pitting or any other indicator that may be of concern, the inspector may determine that a shorter interval to the next internal inspection is required.

How do you prepare for an API 653 internal inspection?

Before an API 653 internal inspection, it is essential to prepare the tank properly. The container must typically be taken out of service. This includes draining the tank, cleaning it thoroughly, and removing any debris or residues that may interfere with the inspection. Tank owners must also provide access to the tank for inspectors and ensure that all safety measures are in place.

What happens during the API 653 internal inspection?

API 653 internal inspections are conducted by certified inspectors who have been trained in the specific techniques and methods required for this type of inspection. Here's what typically happens during an API 653 internal inspection:

- Visual inspection: Once the tank is ready, the inspector enters the tank and conducts a visual inspection of the interior surfaces, including the shell, roof, and floor. The inspector looks for signs of corrosion, pitting, cracks, bulges, and other defects that could impact the tank's structural integrity.

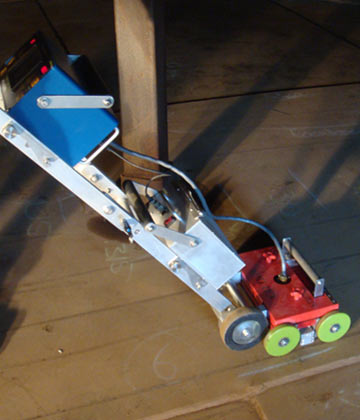

- Non-destructive testing (NDT): The inspector may use various NDT methods to detect issues that are not visible during the visual inspection. These methods can include ultrasonic thickness gauging, magnetic particle testing, magnetic flux leakage testing, penetrant testing, or radiographic testing.

- Documentation review: The inspector will review the tank's records and history to identify any previous issues, repairs, or modifications that could impact its current condition. The inspector may also review the tank's design and construction documents to ensure that it was built to meet the necessary safety standards.

- Final report: The inspector will prepare a comprehensive report summarizing the inspection findings. The report will include essential details on any issues discovered, recommendations for repairs or maintenance, and a timeline for any necessary follow-up inspections.

In conclusion, API 653 internal inspections play a vital role in ensuring the safe operation of tanks. These inspections help to identify potential issues before they lead to tank failures, spills, or other hazardous incidents. While it may be an inconvenience to take tanks out of service, maintaining regulatory compliance will ensure the longevity and safety of the tanks. Regular inspections by API 653 certified inspectors can protect company workers and the environment while ensuring that tanks are reliable for years to come.

-- Genesis Environmental Solutions provides API 653 and STI SP001 storage tank inspections throughout Illinois, Iowa, Kansas, Missouri, Nebraska and Oklahoma. We provide AST services for all types of tanks, including fuel oil tanks. All work is carefully documented and compliant with federal, state and local regulations. Contact us today for more information.